Investment Casting

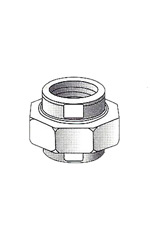

Our wide range of lost wax investment casting services together with machining services, includes automotive parts, pipe fittings, valve parts and more. We provide comprehensive investment casting production services from 3D drawing to finished machine part.

Our lost wax investment casting process consists of the following steps:

1

Based on customer requirements, we propose the best manufacturing method and design a mold.

2

We machine a precise mold from a CAD model. This mold is used to make a wax model.

3

Wax is injected in the mold to create a wax model.

4

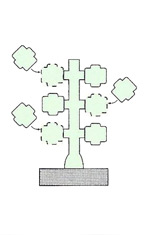

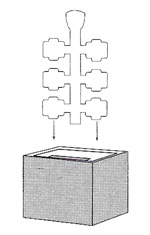

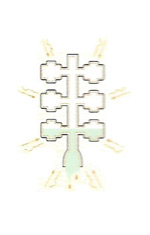

We combine the wax model into a tree (named from its shape)

5

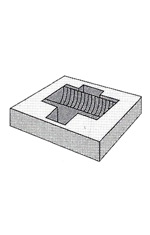

We dip the wax tree into a slurry liquid. Immediately after we coat the tree with heat resistant sand. This process is repeated to create a strong shape.

6

The wax tree is then heated and the wax inside is removed leaving the outer shape.

7

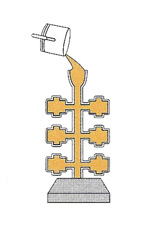

The shape is then baked and heated into a ceramic mold. The mold is then filled with molten metal/stainless steel. The material composition is inspected before being pour into the mold.

8

Branches (containing parts) are removed from the tree.

9

A heat treatment process is used to ensure the structure and hardness of the part.

10

To smooth the surface, we use techniques such as sand blasting, acid treatment, buffing, deburring and polishing.

11

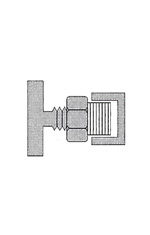

We use a CNC machine to finish the part based on the CAD diagram.

12

We inspect the part’s dimensions and appearance using gauges and measurement equipment. We inspect material composition using non-destructive testing

Machining Equipment

Our capabilities include machining casted parts and parts from round bars. We are experts at any machining. Please contact us with the details of your specific part. We have 15 CNC lathes (DMG Mori, Mazak) and 4 MCs (DMG Mori, Fanuc).

Examples of Minimum and Maximum Sizes

Inconsistent Casting Process Examples

Examples of Casted Parts

Example of small size casted parts. Parts as light as 4.5 kg (9.9 lbs.) can be cast.

Examples of large and small casted parts.

Examples of large size casted parts. Parts up to 25 kg (55.1 lbs.) can be casted.

Example of casted part, maximum weight of 25 kg (55.1 lbs.).

Material Grades of stainless cast steel products

| Type of Stainless Steel Casting | JIS Standard | ASTM Standard | ||

|---|---|---|---|---|

| Austenitic stainless cast steel | JIS G5121 | SCS 13 | ||

| JIS G5121 | SCS 13A | ASTM A351 | CF8 | |

| (SUS304 eq. suitable) | ||||

| JIS G5121 | SCS 14 | |||

| JIS G5121 | SCS 14A | ASTM A351 | CF8M | |

| (SUS 316 eq. suitable) | ||||

| JIS G5121 | SCS 16 | |||

| JIS G5121 | SCS 16A | ASTM A351 | CF3M | |

| (SUS 316L eq. suitable) | ||||

| JIS G5121 | SCS 19 | |||

| JIS G5121 | SCS 19A | ASTM A351 | CF3 | |

| (SUS 304L eq. suitable) | ||||

| JIS G5121 | SCS 21 | ASTM A351 | CF8C | |

| (SUS 347 eq. suitable) | ||||

| Ferritic stainless cast steel * | (SUS 430 eq. suitable) | |||

| (SUS 436L eq. suitable) | ||||

| (SUS 430J1L eq. suitable) | ||||

| ASTM A743 | CB30 | |||

| Martensitic stainless cast steel | JIS G5121 | SCS 2A | ASTM A743 | CA40 |

| (SUS 420J2 eq. suitable) | ||||

| Precipitation Hardening stainless cast steel | JIS G5121 | SCS 24 | ASTM A747 | CB7Cu-1 |

| (SUS 630 eq. suitable) | ||||

| (Austenitic・Ferritic) Duplex stainless cast steel | JIS G5121 | SCS 11 | ASTM A743 | |

| (SUS 329J1 eq. suitable) | (approxmate equivalent CF20) | |||

| (SUS 329J4L eq. suitable) | ||||

| Heat Resisisting cast steel | JIS G5122 | SCH 22 | ASTM A351 | HK40 |

* Neither JIS nor ASTM standard is available for Ferritic stainless cast steele.

Specifications:

| JIS G5121 | Corrosion-resistant cast steals for general applications |

| JIS G5122 | Heat-resistant cast steels and alloys for general applications |

| ASTM A351 | Standard Specification for Castings, Austenitic, for Pressure-Containing parts |

| ASTM A743 | Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel |

| Corrosion-resistant for general applications | |

| ASTM A747 | Standard Specification for Sttel Castings, Stenless, Precipitation Hardening |

Tolerance Range for Casted Products

| 9 Length (m) | Standard Tolerance ** | Special Tolerance |

|---|---|---|

| 0 ~ 10 | ±0.25 | ±0.15 |

| 10 ~ 25 | ±0.30 | ±0.20 |

| 25 ~ 50 | ±0.60 | ±0.30 |

| 50 ~ 75 | ±0.80 | ±0.50 |

| 75 ~ 100 | ±1.00 | ±0.60 |

| 100 ~ 150 | ±1.30 | ±0.70 |

| 150 ~ 200 | ±1.80 | ±1.00 |

| 200 or more | ±1% | ±1.25 |

** ISE Precision Metal Industry (DILAN) Co., Ltd.