Inspection

We carefully control our quality and inspect for dimensional accuracy, appearance and material composition. A part is inspected at each step in the manufacturing process and any defective parts are removed and not sent to the next process.

We have developed proprietary gauges that quickly determine the dimensional accuracy of threading. We use a Go-No Gauge to check the most critical specs of all workpieces. We also use inspection jigs to test critical dimensions as determined by the project. Combined with other methods such as 3D measurement, hardness testing and metal texture observation, ISE MFG CO., LTD. is committed to delivering quality manufacturing that exceeds customer expectations.

.jpg)

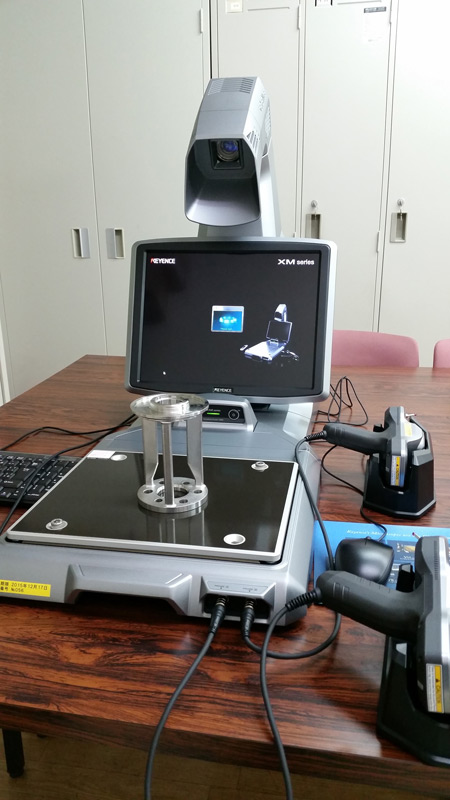

Image Measurement System

Inspecting 3D Dimensions

3D Measuring Equipment

3D Measuring Equipment

Hardness Testing

Pressure Testing

Inspection Gauges